Miller Canvas is an authorized Ozroll Distributor for genuine Ozroll roller shutter components & parts, including the low voltage Ozroll L10 15.121.000 motor assembly powered by the Smart Drive / ODS Control 10 & E-Port Controllers

Miller Canvas is an authorized Ozroll Distributor for genuine Ozroll roller shutter components & parts, including the low voltage Ozroll L10 15.121.000 motor assembly powered by the Smart Drive / ODS Control 10 & E-Port Controllers

IF YOU ARE UNSURE OF THE VOLTAGE SUPPLY YOU MUST CONSULT WITH A QUALIFIED ELECTRICIAN.

PLEASE READ ALL INFORMATION BELOW

PRODUCT INFORMATION (Genuine Part)

Part # 15.121.000 ODS L-10

2 Year Warranty.

The L10 is designed to fit in the Hood End Plate, rather than inside the axle like other motors. Mounted to the end plate via two mounting holes located at the front.

The L10 is housed in tough die-cast aluminum housing and is supplied with 2m of cable attached with spade connectors also attached, that connects to the wall plate. (5m is the maximum length of cable permitted).

The L10 is suitable to most Hood End plates 160mm and above.

Technical Specifications - e-series L10

Nominal Torque: 10Nm

No Load Speed: 16rpm

Max Operating Current: 3.6 Amps

Nominal Voltage: 14 volts

Internal End Stop Limits: 18 turns (in other words the motor turns 18 revolutions then stops automatically it can then be operated to turn in the other direction and stops after 18 revolutions).

The Ozroll L10 Has A Maximum Lifting Capacity of 16kg

Curtain weight: 1sq mtr = 4kg = 4square meter of shutter (for example, 2000mm x 2000mm window maximum) or any other combination that equals 4 square metres or less.

THERE ARE THREE VERY COMMON SIGNS YOUR MOTOR NEEDS REPLACING.

- Pressing the up or down button results in only a few millimeters of movement.

- Pressing the up or down button results in a jiggle of the shutter curtain then it stops, pressing again results in the same.

- Pressing the up or down button results in a ticking noise in the head box with no movement of the shutter curtain.

PLEASE NOTE:

You may be replacing an old Mech 10 Motor (pictured below on the RH Side) these are no longer available and have been superseded by the L10 motor (pictured below on the LH Side) NOTE THE WORDING ON THE STICKERS, THEY ARE EASY TO IDENTIFY.

Note the white and black sticker/labels on the two motors below RH side says "SMART MECH 10" LH side says "ODS - L10". The MECH 10 is now superseded and no longer available the ODS - L10 is the replacement but you will need the adapters listed below.

IMAGE BELOW CLEARLY SHOWS THE OLD MECH 10 MOTOR

If replacing the old Mech 10 motor you will need one of the axle adapters below, as well as a Red Axle Insert, for the Idler end on a 50mm round aluminum axle.

Note the white and black sticker/label on the motor if it says "SMART MECH 10" it is now superseded and no longer available the ODS - L10 is the replacement but you will need the adapters listed below.

Axle Adapters 50 mm Round is the most common.

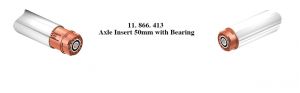

Red Axle Insert with bearing (below) goes on the opposite end to the motor.

NOTE: IF RETROFITTING from Strap control or Mech 10 and using a new Red Axle Insert (below) the 50mm round axle cut length is box width os-os less 96mm.

.jpg)

THIS IS A LOW VOLTAGE 14v System it is relatively easy for a handyman to achieve a motor changeover or retrofit, download the instructions "Click Here"

IF YOU ARE UNSURE OF THE VOLTAGE SUPPLY YOU MUST CONSULT WITH A QUALIFIED ELECTRICIAN.

IMPORTANT

Once the motor is installed and working, before engaging the axle and shutter curtain to the motor - run the motor in the downward direction until it stops itself, this may take some time as the motor limits are set at 18 revolutions for shutters up to 3m in height. (In simple terms the motor counts the number of revolutions and stops at a predetermined count of 18) Press the down button again to ensure its fully down, then simply insert the axle into the motor by aligning the spline on the axle adapter, rotate the axle so that the back of the top curtain slats sit against the back of the box.

Resistance causes the motor to stop on the way up (at the top) this is achieved by using stops in the shutter guide. Basically, the controller senses a large change in current draw and turns the motor off. This means there are no limit settings required during installation.

HANDY HINTS to achieving a successful changeover:

1) The shutter curtain must be all the way down and the axle exposed.

Firstly ensure your controller is sufficiently charged or use a controller from a window you know is working.

- Press the down button multiple times until the curtain is down (it may only move a few mm at a time).

- If you get no movement pressing the down button, have someone outside hit the end of the headbox where the motor is with a rubber mallet or hammer with a block of wood whilst the down button is pressed (this seems to sometimes be enough for the brushes to make contact for short intervals).

2) Once the curtain is down if you can't rotate the axle.

To access all pop rivets securing the idler end you may have to cut through the old Mech 10 tube insert assembly immediately at the end of the axle (NOT THE AXLE).

3) Pulling out the 12v wiring.

OTHERWISE, FOLLOW THE METHOD BELOW

The wiring cable may pass through some very small holes and pass around tight metallic (Aluminium) corners. If its a standard installation as recommended by Ozroll the wire loom exits the headbox and passes down a cavity in the roller shutter guide track (found on each side of the roller shutter) then exits the leg guide at a point level with the controller mount inside the house, and passes through the wall, sometimes through holes with only 8-10mm in diameter.

- Inside the house remove the plastic controller mounting cradle from the wall and disconnect the wiring by detaching the spade terminals. CONSULT WITH A QUALIFIED ELECTRICIAN if you have any doubt about the system.

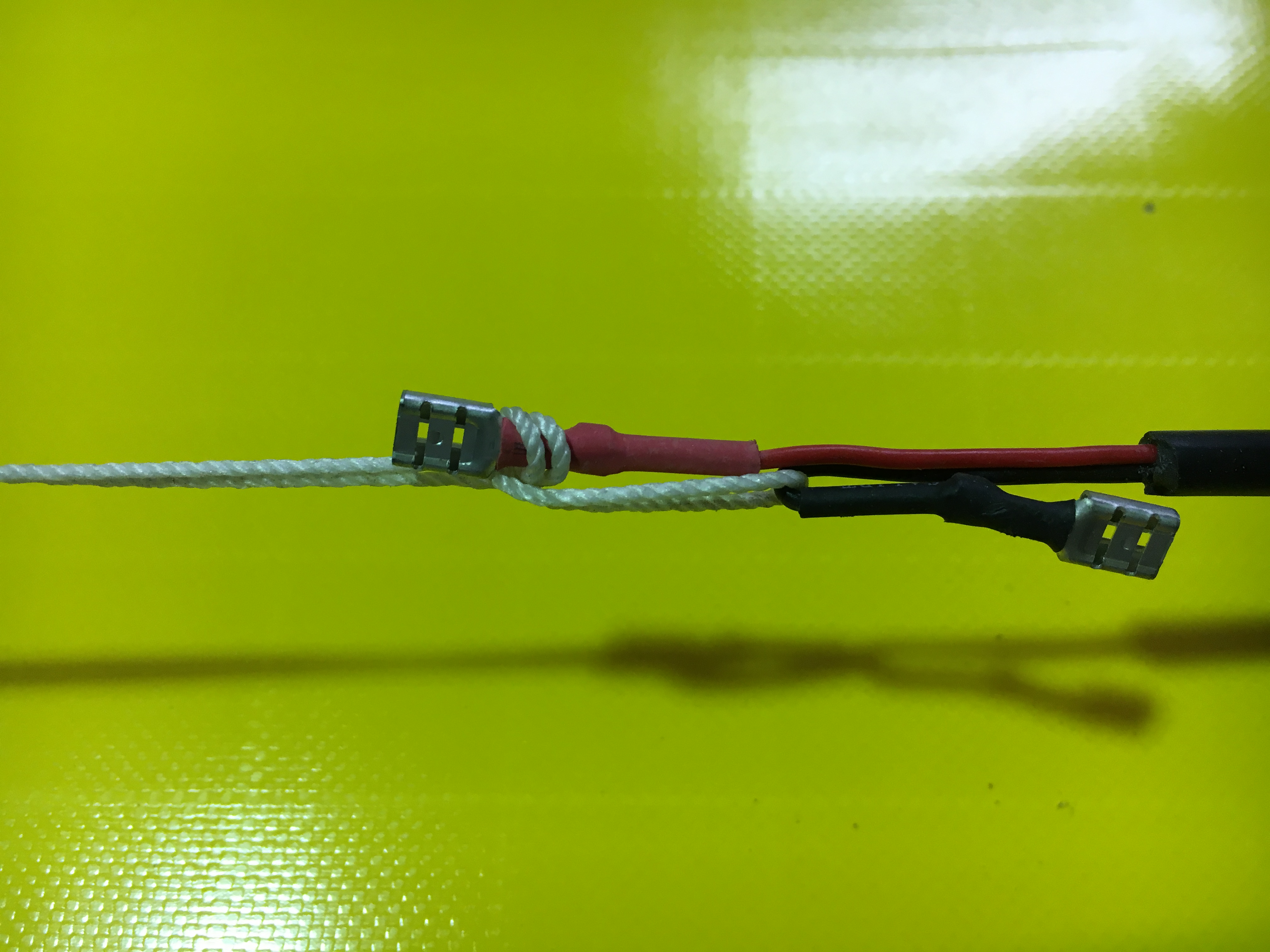

- Tie some strong string to the cable ends where spade terminals are I use builders string doubled and looped (see image below).

- Tightly cover with electrical tape but ENSURE the overall diameter is no larger than the black plastic sheath covering the red and black wires and ENSURE the whole winding remains flexible (don't wind too much tape.).

- Pull as much wire from the wall as possible and lubricate with CRC or silicone spray.

- Go outside and find where the wire exits the headbox and apply liberal amounts of CRC etc. down the hole if exiting into the curtain guide track.

- Pull the wiring out, you may need someone inside giggling the wire whilst attempting to remove.

- It may be necessary to partially remove the screws securing the guide track to access the wire and feed it around the corner.

- Simply reverse the process to install the wiring.

4) 50 mm Round Axle cut length and keyway

- If you are retrofitting from an old strap control or old Mech 10 motor and using the red axle insert the axle cut length is Hood Box outside to outside measurement LESS 96mm.

- A 25 x 4mm slot will need to be cut lengthways into the motor end of the axle to accommodate a key on the black plastic axle adapter.

IMPORTANT ****SETTING THE MOTOR BOTTOM STOP POSITION****

5) Before engaging the axle and shutter curtain to the motor

- Test for correct motor direction when pressing controller buttons if incorrect simply swap wires on the controller.

- Run the motor in the downward direction until it stops itself, this may take some time as the motor limits are set at 18 revolutions (in simple terms the motor counts the number of revolutions and stops at a predetermined count of 18)

- Simply insert the axle into the motor by aligning the spline on the axle adapter with the female spline receptor in the motor, correct alignment is when the back of the top curtain slats sit against the back of the box a security measure so that the top of the curtain engages with 2 x slat cut offs fixed at the top of the back of the box.

- The straps which connect the curtain to the roller should not wind beyond any comfortable position (slightly bent is allowable)

- The top stop is automatic and does not need setting. The curtain is physically stopped from winding all the way into the top box by a black plastic "V" Stopper on each end of the bottom rail, the controller on the wall notes a large change in current draw and turns off the lifting circuit.

TEST by running the shutter through several up and down cycles, if successful reinstall the Hood Box cover. that's it your done.

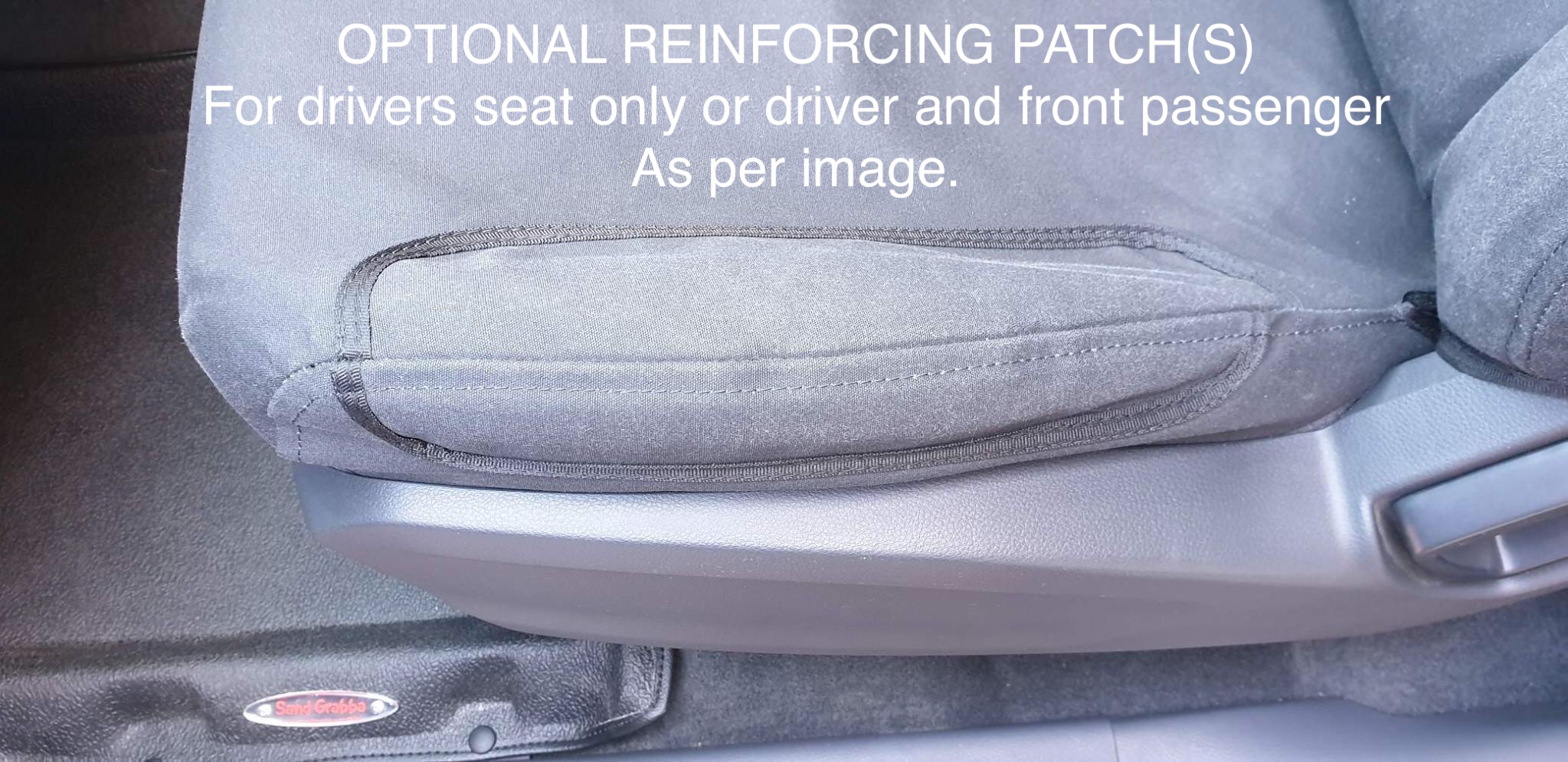

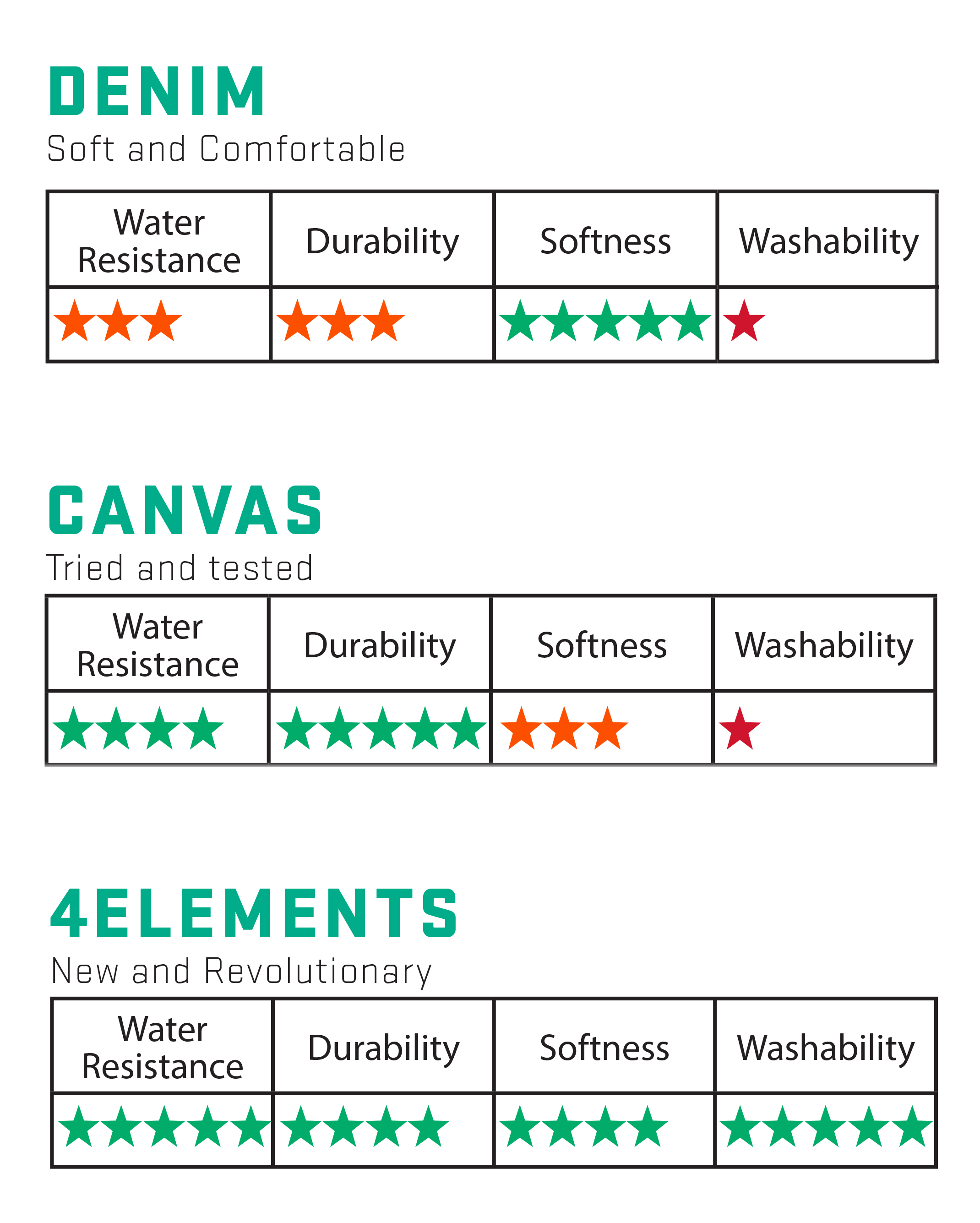

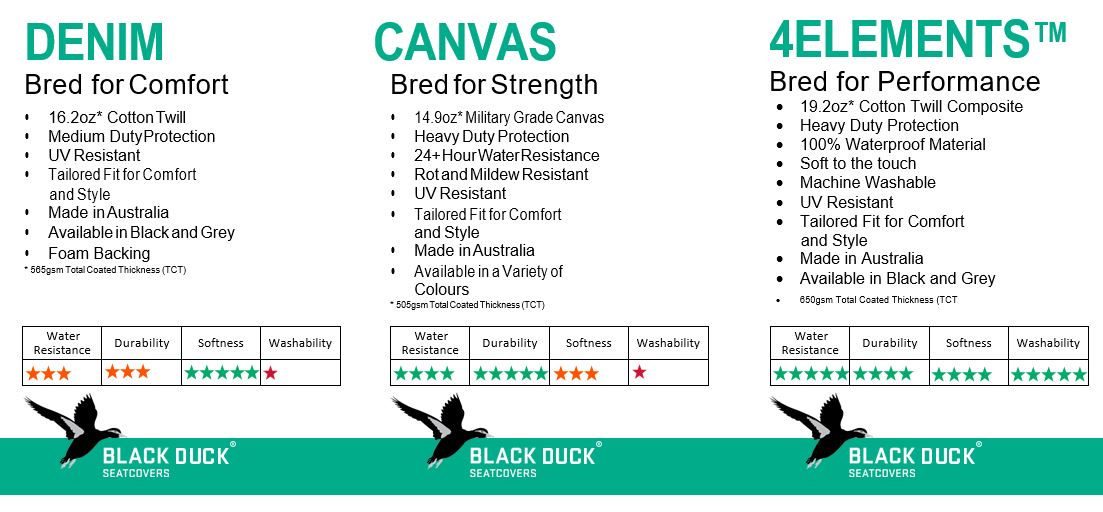

INTRODUCING BLACK DUCK'S REVOLUTIONARY NEW HEAVY DUTY WASHABLE (but without detergent) SEAT COVER FABRIC

NOW AVAILABLE on ALL OUR BLACK DUCK COVERS, SIMPLY SELECT "4ELEMENTS ELBK" as an OPTION in our FABRIC & COLOUR OPTIONS SELECTOR.

Available in BLACK or GREY.

.jpg?1554150803331)

Bred for Strength and Comfort

Developed exclusively for Australian conditions by Black Duck Seat Covers, the Pioneers of Seat Protection, 4ELEMENTS is a fabric that will revolutionize the seat cover industry.

4Elements by Black Duck Seat Covers are tested to withstand tough conditions without compromising on comfort. Featuring a 19.2oz Cotton Twill Composite, this is a heavyweight product with a soft and flexible feel for the ultimate in seat protection. Made from a 100% waterproof fabric that is also machine washable (but without detergent) to keep your vehicle interiors in pristine condition – you won’t be disappointed!

Black Duck's most advanced seat cover yet!

- 19.2 oz Cotton Twill Composite

- Heavy Duty Protection

- 100% Waterproof Fabric

- Soft and Flexible

- Machine Washable (no detergent)

- UV Resistant

- Tailored fit for comfort and style

- Available in Black or Grey

You may already know that Black Duck manufacture the BEST premium quality Canvas or Denim Seat Covers for use in Australias harsh unforgiving conditions, now with the introduction of the all-new 4ELEMENTS seat cover fabric, Black Duck has set the bar even higher.

SIMPLY SELECT "4ELEMENTS" in Black or Grey in our Fabric & Colour Selector.

**PLEASE NOTE**

AS OF 15/05/2021 DENIM IS NO LONGER AVAILABLE DUE TO SUPPLY ISSUES.

No posts found

SHIPPING

All Ozroll products are shipped via Express Post.

- A flat rate $15.00 Postage charge (per order wether for 1 item or several items) is added at the cart.

- Posted direct from the Ozroll Factory/Warehouse in Adelaide.

- Within 48 hours of receiving your completed payment.

- You will be notified via email once shipped.

WARRANTY and RETURNS

Miller Canvas is committed to providing quality products to our customers. If for any reason you are not completely satisfied with any product supplied by us, please contact us by emailing sales@millercanvas.com.au within 7 days of receiving the goods.

You must:

- Include your Name, Address and Tax Invoice number in the email.

- Provide a clear and detailed description of the problem you are experiencing.

- No product is to be returned without authorisation and an accompanying CUSTOMER CLAIM FORM issued by Miller Canvas.

- Any return will be to Ozroll and not Miller Canvas unless otherwise directed.

- Return packaging must be of sufficient quality to protect the goods in transit.

- You are responsible for ANY return costs of the goods back to Ozroll.

- Different products have varying warranty periods generally stated on the product description page.

- Upon return Ozroll technicians will inspect and test the component and will repair or replace the item and ship it back to you.

- Guarantees do not apply if you got what you asked for but simply changed your mind, found it cheaper somewhere else, decided you did not like the purchase or had no use for it.

In addition to manufacturers’ guarantees on selected products, Miller Canvas and its suppliers provide a guarantee of acceptable quality on every product, by law. You are entitled to a replacement or refund for a major failure, and to compensation for other reasonably foreseeable loss or damage. You are also entitled to have the goods repaired or replaced if the goods fail to be of acceptable quality but the failure does not amount to a major failure. This refund policy is not intended to exclude or limit any rights which you may have under the Competition and Consumer Act 2010 (Cth) or equivalent State or Territory laws.

Shipping, Warranties & Returns for Black Duck Products

SOME FACTS

- Not all covers are in stock, Black Duck have more than 1400 patterns and 15 available fabric and colour combinations. Our experience in selling Black Duck covers online for more than four years shows that approximately 40% of orders need to be manufactured. Current manufacturing time is an awsome average of 8 days.

- All orders are shipped direct to you from Black Duck via Star Track Overnight Express (Example: a customer in Mt Isa ordered at 2:00pm and received their covers at 10:00am next day)

- We have a flat rate shipping charge of $18.00 per order INCLUDING INSURANCE. Australia wide.

- Compare our prices, some companies offer free shipping then charge you for EXPRESS shipping with an additional charge for INSURANCE.

- Immediately after a transaction you are emailed our Tax Invoice this email is headed with a request for you to click on a link to fill out our Seat Cover Form. We Guarantee you will get the correct covers for your vehicle if you fill out the form with correct information about your vehicle and the seat configuration. YOUR ORDER WILL NOT BE ACTIONED UNTIL THIS FORM IS FILLED OUT CORRECTLY.

Delivery Charges

Shipping in general is calculated at checkout, OUR Black Duck Seat Covers have EXPRESS DELIVERY as a standard. A delivery fee of $18.00 per order (WE ARE CURRENTLY OFFERING FREE DELIVERY) whether for a single seat cover or a complete set of covers for a Bus to ANY location within Australia. We do not ship to addresses outside Australia. Miller Canvas reserves the right to change prices for delivery at any time.

Addresses & Shipping methods

Delivery is generally via Star Track Express. In most cases the article will have to be signed for. Our experience shows that the best delivery outcome is for the customer to provide a delivery address of a business they may be associated with where someone is present to accept your delivery and sign as proof of delivery between the hours of 9:00am and 5:00pm.

If no one is home to accept delivery and sign as proof of delivery the courier will leave a card advising for collection at the nearest Post Office or Startrack depot or agent extra charges may apply.

.

Delivery Times

All orders on this website are processed within 24 hours Monday to Friday. If there are any unforeseeable delays, you will be contacted by our sales team within 2 business days.

Orders will be delivered in approximately 2 - 10 business days.

Our courier cannot guarantee a specific delivery date or time. If no one is present to accept the delivery, a slip will be left in the mail box so that you can negotiate with the courier a suitable arrangement for final delivery or collection, if a redelivery or change of delivery address is required then the customer is liable for any further charges.

If your Product has not arrived after the estimated delivery time, please contact us via email sales@millercanvas.com.au

Delivery

Please ensure you or someone appointed by you receives the article, inspect it and check the goods at the time of delivery.

The receipt of goods must be signed for by an adult. If there is any defect or damage, (this also includes visible damage to goods or property during the course of delivery), then you must address this with the courier and have it noted on the proof of delivery docket.

Title and risk of loss to all products will pass to you on delivery.

Products Damaged in Transit

Please contact us immediately via email: sales@millercanvas.com.au. Please state your name and the invoice number provided to you by Miller Canvas and clearly outline the problem.

We will not accept liability for visible damage not reported within 7 days of receipt of goods.

NOTE: In case of any problems with your delivery, Miller Canvas will be in direct contact with the Black Duck and the carrier to resolve the issue as quickly as possible with as little inconvenience to you. We will make every effort to contact you and keep you informed of the progress of our investigation.

Seat Cover Returns & Refunds.

Miller Canvas reseves the right to refuse a return for refund, each case is decided upon merrit.

Returns will only be accepted if prior approval and a return reference form is given, the purchaser must contact us via email to sales@millercanvas.com.au within 7 days of delivery, with a complete detailed description of the issue, please include your Tax Invoice number.

All returned items (aside from warranties) must be:

- Unused and in their original condition.

- The Full set of covers as purchased.

- Part of our Standard color range eg. grey, black or brown canvas or black or grey denim. Non-standard colour items cannot be returned

- Accompanied by a Return Authorisation Form provided by us on approval of your Return Request Submission.

- The customer is responsible for all return costs.

- The customer must issue Miller Canvas with a tracking reference.

- A full refund will be issued less our original shipping costs of $40.00 (Miller Canvas reserves the right to change these costs at any time)

If the item is not returned in as new condition in its original packaging along with all documentation, you may also be charged a restocking fee (to be determined upon inspection).

Seat covers for older model (non-current model) vehicles, and change of mind issues will only be accepted for return at the discretion of Miller Canvas. This can be very costly, so please contact us to ask any questions about Black Duck seat covers. Miller Canvas will not refund items that have been misused, mishandled or incorrectly installed.

Black Duck 100% Satisfaction Guarantee*

If you are not 100% satisfied with your Black Duck® Seat Covers, we offer you a full money

back* guarantee, because we have 100% confidence that our product will add value to your

investment!

*Terms & Conditions - 100% Satisfaction Guarantee for Black Duck® Seat Covers:

- This warranty is given by Qualtarp Pty Ltd trading as Black Duck Seat Covers (“Black Duck”).

- This warranty is valid for 12 months after purchase (“term of warranty”).

- In order to claim this warranty, you must request a return form from our customer service staff, and the product must be sent to the address provided on the form together with proof of purchase within the term of warranty.

- Black Duck will refund or replace the purchased product once it is received.

- The purchaser must bear all costs associated with the delivery and return of the product to Black Duck. Black Duck may, in certain circumstances and entirely at its discretion, reimburse the purchaser for delivery costs incurred in returning the product to Black Duck for refund or replacement.

- Black Duck accepts no responsibility for non-delivery of a product seeking to claim this warranty.

- This warranty does not apply to Loose Fit, vinyl or fabric seat covers.

This warranty is in addition to rights and remedies available to you under the Competition and Consumer Act 2010 (Cth).

Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are entitled to a replacement or refund for a major failure and compensation for any other reasonably foreseeable loss or damage. You are also entitled to have the goods repaired or replaced if goods fail to be of acceptable quality and the failure does not amount to a major failure.

Please direct all warranty claims direct to Black Duck

Phone: 1800 803 825

Fax: 08 8723 6347

Email: sales@blackduck.com.au

In addition to manufacturers’ guarantees on selected products, Miller Canvas and its suppliers provide a guarantee of acceptable quality on every product, by law. You are entitled to a replacement or refund for a major failure, and to compensation for other reasonably foreseeable loss or damage. You are also entitled to have the goods repaired or replaced if the goods fail to be of acceptable quality but the failure does not amount to a major failure.

Shipping, Warranties & Returns for Topaz Global seat covers.

SOME FACTS

- Not all covers are in stock, most are and are generally shipped within 2 work days via Express Post with tracking.

- When you select an optional colour and or optional foam padding these are a custom order and may take up to 10 work days for dispatch.

- All orders are shipped direct to you from our supplier Topaz Global in WA

Delivery Charges

In General shipping is free for any Topaz Global Seat Cover, our shipping costs are $22.00. In the event of a return for refund being requested we will deduct $22.00 from any refund due and the customer is responsible for any return shipping costs.

Addresses

Please use your normal Postal Address.

Delivery

Please ensure you or someone appointed by you receives the article, inspect it and check the goods at the time of delivery.

Title and risk of loss to all products will pass to you on delivery.

Products Damaged in Transit

Please contact us immediately via email: sales@millercanvas.com.au. Please state your name and the invoice number provided to you by Miller Canvas and clearly outline the problem.

We will not accept liability for visible damage not reported within 7 days of receipt of goods.

Seat Cover Returns & refunds.

The purchaser must contact us via email sales@millercanvas.com.au within 7 days of delivery with a complete detailed description of the issue. Returns will only be accepted if prior approval and a return reference number is given.

All returned items (aside from warranties) must be:

- Unused and in their original condition.

- The Full set of covers as purchased.

- Part of our Standard color range eg. grey

- Accompanied by a Return Authorisation Form provided by us on approval of your Return Request Submission.

- You will be responsible for paying the full return freight.

- Any refund due will have our shipping cost of $22.00 deducted.

- You will be charged a restocking fee of up to 10%.

Non-standard colour or optional padding items cannot be returned.

When you select an optional colour or optional padding thes covers are custom made and cannot be returned.

In addition to manufacturers’ guarantees on selected products, Miller Canvas and its suppliers provide a guarantee of acceptable quality on every product, by law. You are entitled to a replacement or refund for a major failure, and to compensation for other reasonably foreseeable loss or damage. You are also entitled to have the goods repaired or replaced if the goods fail to be of acceptable quality but the failure does not amount to a major failure.

Please Note: They may not be of the covers you are considering each seat has a cover custom designed to suit.

TYPICAL MOTORBIKE SEAT COVER - Custom designed for each seat.

IMAGE SHOWS A HONDA QUAD fitted with a separate tank cover and a separate seat cover, (note the handmuffs also available from Miller Canvas)

ALL IN ONE PADDED SEAT AND TANK COVER

TYPICAL ATV COVER they are custom designed for each seat.

Canvas Seat Cover to suit YFM700 KODIAK 2016 – Current

ALL IN ONE PADDED CANVAS SEAT and TANK COVER to suit Honda XR 250 & 400

Canvas Seat Cover to suit Ranger XP900 - P799Q1

CANVAS SEAT COVER TO SUIT YXC700 VIKING VI 6 SEATER (SET OF 3) Y822Q1-2

Y822Q1-2.jpg?1518593340507)

CANVAS SEAT COVER TO SUIT A KUBOTA MOWER

TOPAZ GLOBAL KUBOTA EXCAVATOR-1

TOPAZ GLOBAL JOHN DEERE 855D

CanAm UTV seat cover.

.JPG?1518594130666)

TOPAZ GLOBAL KUBOTA UTV

YFM450 KODIAK All-in-One padded seat and tank cover